Technology and equipment to increase rate of penetration (ROP) and number of bits saving

INCREASING THE SPEED OF DRILLING

The process of drilling is an energetic process; the rock destruction requires a certain energy supplied to the bit, which is divided into two components: the mechanical energy (the weight on the bit (WOB) and the frequency of rotation) and hydraulic power (mud pumps productivity and developed pressure). On the other case, the destruction of rock is influenced by the following factors: the mechanical properties of the rock, the presence of the pore, formational, differential and total hydrostatic and hydrodynamic pressures.

Numerous laboratory and field studies were conducted illustrating the effect of these factors on rock destruction behavior. Following information was observed as a result:

1. Differential pressure is one of the main factors determining the performance of bits.

2. Intensive decrease of ROP takes place at the initial stages of differential pressure increase up to 509 psi. The further increase of differential pressure (P) is associated by stabilization of ROP (Vm).

3. Decreasing differential pressure increases ROP.

4. With increase of applied weight on the bit, increases the sensitivity of ROP to differential pressure change.

5. It is impossible to detect a common relationship Vm = Δf ( P) based on results of the test drilling.

So at the present it is considered that on the current drilling modes the differential pressure appears usually as the main determining factor on the cost-performance characteristics of drilling. An increase in Δ P up to 203-1015 Psi, depending on drilling conditions, ROP can be reduced for 2-5 times.

Based on recent information, differential pressure causes the static forces holding the sludge at the bottom, numerical coloration equal to the difference between hydrostatic pressure and reservoir (pore). However on the circulation of drilling fluid the hydrodynamic pressure rises, which also impacts depressant on the bottom hole. Consequently, the circulation of drilling mud acts on a bottom hole as depressant pressure, which is the sum of the differential and hydrodynamic pressures.

Since the mid 70's of the last century American companies have begun the research in drilling ejector devices application. There were created bits with pointing up nozzle and near-bit ejector devices but for a different reasons these technologies are not widely used.

Using the accumulated experience we have developed the near-bit ejector unit (NBEU) and methods to optimize, including the choice of rheological parameters of drilling fluid in the cylinder diameter

Using the accumulated experience, we have developed the above-bit ejector pump and methods to optimize the wells washing hydraulic program including the selection of rheological parameters of drilling fluid, the diameter of a cylinder productivity mud pumps, as well as the calculation of bit’s nozzles number and sizes.

Pic.1 – A - Near-bit ejector unit (NBEU) appearance; B - The scheme of NBEU work: I – bit; II – NBEU; III - downhole motor; IV - drilling pipes. Arrows indicate the direction of of fluid motion

NBEU operates as follows. Hydraulic calculation is produced and size calculated nozzles are installing on the bit. After that NBEU is installed on the bit and bottom hole assembly (BHA) on the top. Collected BHA is coming down and to the working area of the bit and NBEU supplies drilling fluid; a portion of drilling fluid passes through the bit’s nozzles and uses to clean the slaughtering, and some uses in work with NBEU. When a drilling mud goes the jet pump nozzle, high-pressure jet enters the mixing chamber, where expanding, transfers its energy to the mixing chamber liquid. Due to the high velocity of the mixed stream at the junction of the mixing chamber and supply channel there creates a negative pressure and the liquid from the drilling bit zone together with the slurry exits through the supply channels into an annular space, strikes the borehole wall, filling the pores. Due to the high velocity of the fluid in the annular space and the limited distance between the borehole wall and the NBEU casing in this annular space is created an additional ejection effect; during the NBEU work creates a two-stage ejection that allows you to create a significant depression in bit working area.

|

№ |

Oilfield |

Drilling interval; bore hole diameter, ft; inch |

ROP, feet per hour |

Bit footage, feet |

Characteristic increment, % |

Savings of bits |

� | |||

|

ROP |

Bit footage |

� | ||||||||

|

basic |

withNBEU |

basic |

withNBEU |

� | ||||||

|

1 |

Mirzoevo (rotary drilling) |

2296-6562; 11,6 |

26 - 32 |

59 - 72 |

492-656 |

1476-1640 |

125 |

200 |

5 |

� |

|

6562-11810; 8,5 |

8 - 12 |

16 - 23 |

230-328 |

722 |

100 |

120 |

8 |

� | ||

|

2 |

Saratovskoe UBR (rotary drilling) |

4879-5849; 8,5 |

5 |

10 |

118 |

243 |

112 |

105 |

2 |

� |

|

3 |

Chernogorskoe (turbo drilling) |

138-3323; 11,6 |

78 |

137 |

1969 |

3281 |

75 |

66 |

1 |

� |

|

4 |

Ershovoe (turbo drilling) |

6889-9842; 8,5 |

28 |

37,5 |

153 |

234 |

33 |

53 |

2 |

� |

|

5 |

Kijazlinskoe (turbo drilling) |

3943-4380 |

21 |

37 |

- |

- |

73 |

- |

- |

� |

|

6 |

Melnikovskoe (rotary drilling) |

4173-4741 |

6 |

38 |

- |

- |

445 |

- |

- |

|

In 2008 in "Tatneft" corporation there were conducted NBEU acceptance tests on four wells. Table 1 shows the average data for drilling performance increasing in "Tatneft".

|

Field |

Average values of the base wells |

Average values for the wells drilled by NBEU |

||

|

Mechanical speed, m/min |

Penetration on the bit, m |

Mechanical speed, m/min |

Penetration on the bit, m |

|

|

Upland area |

25.1 |

- |

34.8 |

- |

|

Chishminskaya area |

20.47 |

187 |

29,39 |

304 |

|

Karamalinskaya area |

17.2 |

268 |

22 |

400 |

|

Alkeevskaya area |

14.8 |

202 |

20.1 |

300 |

By the results of this work it is recommended by a commission the adoption of the industrial use of this technology.

We continued the work increasing the penetration rate using NBEU on the fields of Commercial and industrial chamber "TatRITEKneft" in September and October 2012.

|

Field |

Average values of the base wells |

Average values for the wells drilled by NBEU |

||

|

Mechanical speed, m/h |

Penetration on the bit, m |

Mechanical speed, m/h |

Penetration on the bit, m |

|

|

Enorusskinskinskoe #1472 bit 295.3mm |

20.6 |

- |

31 |

- |

|

Enorusskinskinskoe #1472 bit 215.9mm |

17.6 |

- |

25.1 |

- |

|

Melnikovskoe #2491 bit 215.9mm |

16 |

- |

22.2 |

- |

On the well #1472 of Enorusskinskoe field NBEU application with a 295.3 mm chisel increased mechanical speed of drilling on 51%. And a drilling bit with a diameter of 215.9 mm chisel with NBEU increased a penetration rate for 42%. On the well #2491 of Melnikovskoe field drilling bit (215.9mm) using NBEU increased a speed of drilling for 38%. As well NBEU were tested during the drilling of 295.3mm chisel on Bovanenkovskoye field to identify opportunities of ejector pump to prevent the formation of "oil seals" on BHA elements and keep trunk diameter close to face value. Drilling was carried out in the upper intervals in the permafrost zone.

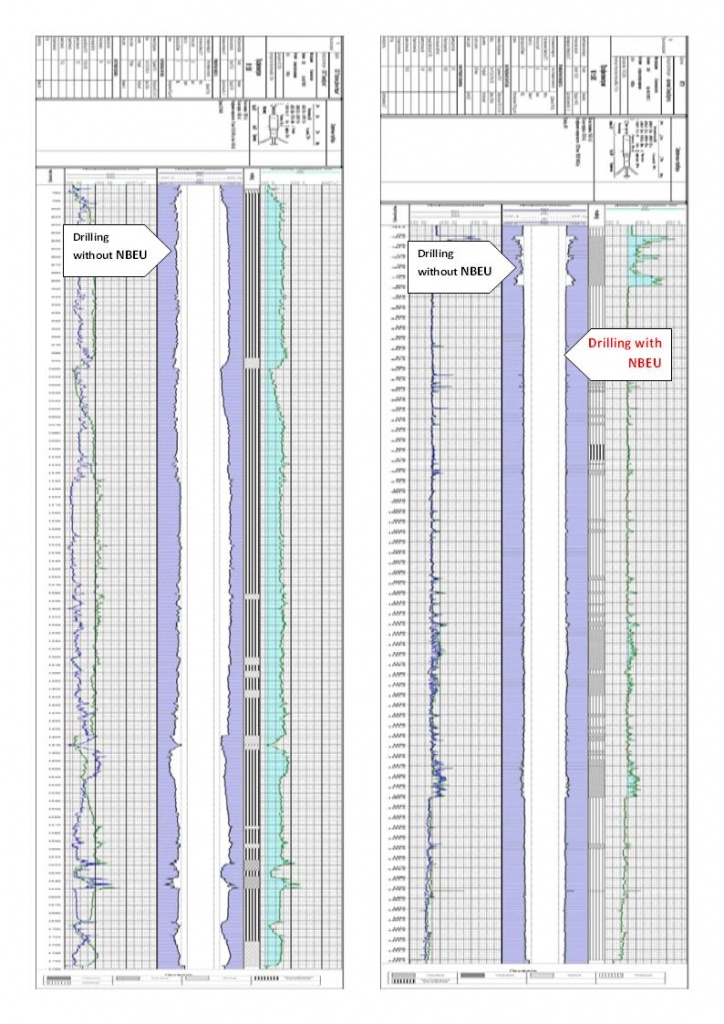

Pic.2 - Caliper logging of two adjacent wells.

As it seen from the caliper logging on picture 3, the interval drilled without NBEU (left caliper log) include caving zones, while well drilled using ejector pump has a diameter close to the face value. The lack of "oil seals" is noted during the lifting facility with NBEU.

Experimental work was carried out in Libya, the company AGOCO, Oman, PDO Company in the United Arab Emirates, company ADCO.

Libya

Drilling was carried out on Sarir field using NBEU in 2008, rotary, bit size was 215.9 mm. All data are presented in Table 3.

|

Day drilling |

Drilling depth, ft |

Penetration, ft / day |

Mechanical drilling time, hour |

Mechanical speed, ft / hour |

% mechanical speed growth |

||||

|

L-79 |

L-81 |

L-79 |

L-81 |

L-79 |

L-81 |

L-79 |

L-81 |

||

|

1 |

7988 - 8200 |

7473 - 7820 |

212 |

347 |

14 |

16 |

15 |

21.0 |

40.0 |

|

2 |

8200 - 8440 |

7820 - 8350 |

240 |

530 |

21 |

21 |

12 |

25.0 |

108.3 |

|

3 |

8440 - 8717 |

8350 - 8390 |

277 |

40 |

22 |

3 |

12.5 |

13.3 |

6.7 |

|

4 |

8717 - 8800 |

8390 - 8436 |

83 |

46 |

8 |

6 |

10 |

14.3 |

43.0 |

|

5 |

8800 - 8975 |

8436 - 8830 |

175 |

394 |

21.5 |

21 |

8 |

18.7 |

133.8 |

|

6 |

8975 - 9045 |

8830 - 9075 |

70 |

245 |

10 |

18.5 |

7 |

13.2 |

89.2 |

|

7 |

9045 - 9075 |

|

30 |

|

3 |

|

10 |

|

|

|

|

7988 - 9075 |

7473 - 9075 |

1087 |

1602 |

99.5 |

85.5 |

10.9 |

18.7 |

71.5 |

As a result of the use NBEU with 215.9 mm drill chisel at the downhole #L81-65, compared with the same drilling bit in the borehole diameter #L79-65 (standard BHA without NBEU) are made the following conclusions:

- Drilling speed was increased by 71.5%.

- Drilling time interval was reduced by 41.8% (61.5 hours).

In the well #L81-65 (drilling with NBEU) were used two bits (215.9 mm). They were covered for 1602 feet. The average penetration of the bit was 804 feet.

In the well #L79-65 (drilling without NBEU) were used three bits of the same diameter. They were covered for 1087 feet. The average penetration of the bit was 362 feet.

Pic.4 – Daily penetration of the well #L81-65 (with NBEU) and the well #L79-65 (basic) during the drilling intervals by 215.9 mm chisel with the same rig.

Also the drilling with ejector unit is conducted at Mesla field. Rotary drilling was performed with drilling bit; diameter was 215.9 mm. Data of a base hole is shown in Table 4.

Data from the drilling using NBEU at Mesla field (1)

|

Bit |

Serial number |

Drilling interval, ft |

Penetration, ft |

Time, hours |

Mechanical speed |

Bit wear |

|||

|

ATJ-G8 347 |

6070867 |

7415 |

7900 |

485 |

40 |

12,1 |

T |

B |

G |

|

4 |

4 |

I |

|||||||

|

GT-30C 547 |

6069772 |

7900 |

7906 |

6 |

2,5 |

2,4 |

T |

B |

G |

|

new |

|||||||||

|

GT-20 517 |

5145694 |

7906 |

9160 |

1254 |

83,5 |

15,0 |

T |

B |

G |

|

7 |

7 |

6 |

|||||||

|

GT20 517 |

5155250 |

9160 |

9230 |

70 |

7 |

10,0 |

T |

B |

G |

|

2 |

3 |

I |

|||||||

|

Total |

|

7415 - 9230 |

1815 |

133 |

13,6 |

|

|

|

|

For drilling the interval 7415 - 9230 (1815 ft) in the wells #HH99-65 (standard drilling without NBEU) were used 4 bits: high penetration to the bit without NBEU is 605 feet. For drilling the interval 7395 - 8583 ft (1588 ft) to the wells #100-65 (drilling via NBEU) was used only one bit (table 5).

Data from the drilling using NBEU at Mesla field (2)

|

Bit |

Serial number |

Drilling interval, ft |

Penetration, ft |

Time, hours |

Mechanical speed |

Bit wear |

|||

|

GT-30C 547 |

6069772 |

7395 |

8983 |

1588 |

126 |

12,6 |

T |

B |

G |

|

4 |

6 |

I |

|||||||

|

Total |

|

7395 - 8983 |

1588 |

126 |

12,6 |

|

|

|

|

The average penetration for a bit with near-bit ejector unit is 1,588 feet.

It has to be noted that during the borehole #100-65 drilling via NBEU was used bit GT-30C #547 6069772, which was not used in the well #HH99-65 due to the low penetration rate 2.4 ft/h.

Oman

Drilling with near-bit ejector unit was carried out in Oman on YIBAL KHUFF field in May 2011. There was used rotary drilling with a Reed Hycalog PDC bit, 311.1 mm.

Outcome indicators of drilling:

1. Drilling of the well #YIB-512 (standard BHA without NBEU) for drilling the interval 1427 - 2508m (1081 m) was used the bit with nozzles 6x14 (table 6).

|

Well |

Bit |

Drilling interval, m |

Penetration, m |

Time, hour |

Mechanical speed, meters per hour |

Bit wear |

|

#YIB-512 standard |

DSR619S-I4 |

1427-2508 |

1081 |

94,25 |

11,5 |

2-2-HC-A-X-I-WT-TD |

2. Drilling of the well #YIB-516 (using NBEU)

For drilling the interval 1714 - 2533 m (819 m) was used the bit with nozzles 3x14 and 3x10: (table 7).

|

Well |

Bit |

Drilling interval, m |

Penetration, m |

Time, hour |

Mechanical speed, meters per hour |

Bit wear |

|

#YIB-516 with NBEU |

DSR619S-I4 |

1714-2533 |

819 |

54 |

15,2 |

0-0-WT-G-X-I-WT-TD |

As a result of this work following results were obtained:

- Drilling speed was increased to 32.2%

- The total drilling time interval of 311.1 mm was reduced.

Wear of bit 0-0-WT-G-X-I-WT-TD. Chisel is suitable for further use.

Pic.6 - The state of the bit after well #YIB-516 drilling using NBEU

UNITED ARAB EMIRATES

Drilling with NBEU in ADCO Company (UAE) at the field BAB was carried out at the well #BB-904 in October 2011. Drilling was done with PDM using Smith’s PDC bit with a diameter of 311.1 mm, Type: Si619BHP.

To assess the effectiveness of NBEU, as a base hole, was done the well #BB-874, which was drilled by the same rig crew, in the same area, the same bit (Smith PDC, Type: Si619BHP) and BHA. Data are presented in Table 8.

|

Well

|

Bit

|

Serial number |

Depth, beginning |

Depth, finish |

Drilling interval, ft |

Time, h |

Speed, ft/h |

|

BB-874 |

Si619HEBPX |

JD8746 |

1614 |

6100 |

4486 |

54 |

83,1 |

|

BB-904 NBEU |

Si619HEBPX |

JE9277 |

1622 |

4902 |

3280 |

31,5 |

104,1 |

As a result of work it was found that drilling rate (ROP) in the well #BB-904 (using ejector unit) was increased by 25% compared to #BB-bore 874 which has been drilled (without NBEU) in a similar interval, identical bit with the same drilling parameters. According to the analysis and information from the supervisor and ND-31 drill crew good results were achieved by drilling speed using NBEU.

During the drilling in the bit interval of 311.1 mm was not observed any fluid loss in the range of Simsima formation, which can be considered as the effect of the application for NBEU as a device working like a kolmatator.

The results of this work show that the use of a near-bit ejector unit allows you to:

1. To reduce wells construction time by increasing the mechanical speed of drilling and penetration on the bit;

2. To pass the zones of partial acquisitions with minimal loss of drilling fluid and does not require colmatant entering because the absorption zone mudding is made by drilled cuttings.

3. To save the diameter of the barrel close to the face value and to prevent the “Oil seals" formation.

4. This technology is applicable for rotary drilling and hydraulic downhole motors drilling and does not require a fundamental change in drilling technology adopted for this region.

5. To get a significant economic effect. For example, during the drilling of two wells in Libya was only used one NBEU 203 cost 10000 USD, which allowed the customer to save 176,000 USD only for direct costs (the cost of drilling bits and rent).

References:

1. Kolesnikov N.A. The processes of rock breaking and paths for accelerated drilling. M. Overview. Sep. Drilling. 1983.